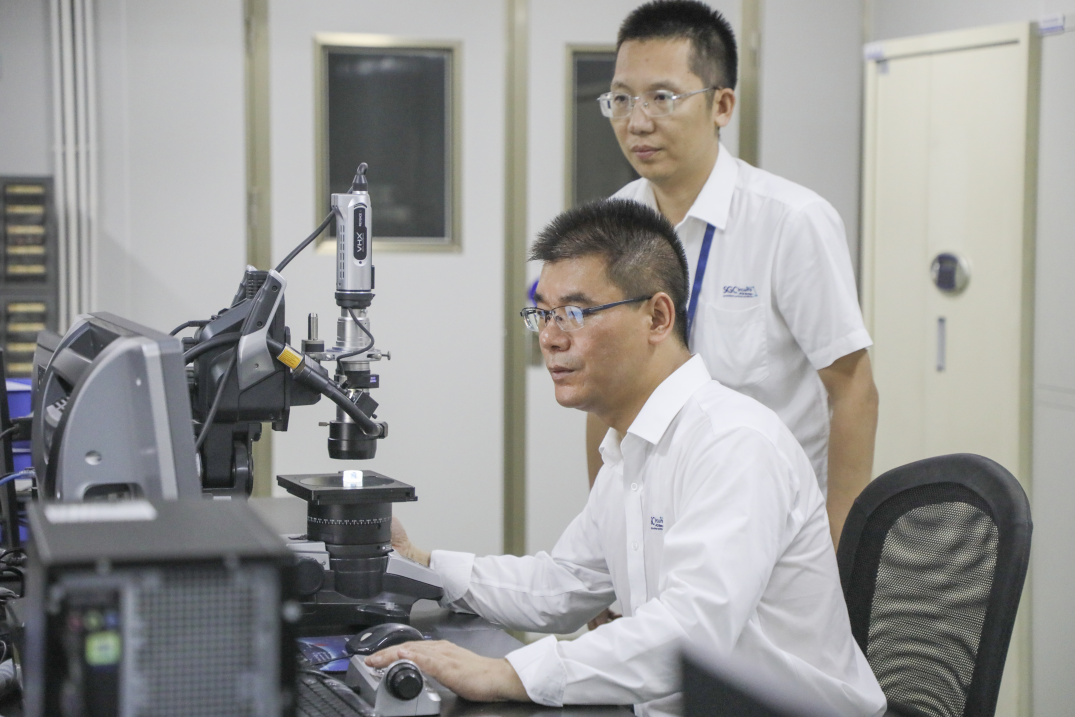

Talent Spotlight: At the end of 2006, Sunshine Global Circuit had never produced HDI PCBs before, and there was a complete lack of relevant process parameters and processing experience. How did he complete the technological research and production of multiple high-order stacked hole HDI orders in less than a month with high quality and on-time delivery? Facing the cultural differences between China and Germany, how did he turn around the operating conditions of the German company? Having already obtained the EU Blue Card and the opportunity for long-term residence, why did he decide to return to China? After returning, how did he lead the company's team to achieve breakthroughs in the construction of digital production lines and key technological research?

Talent Profile: He previously served as the General Manager of Germany Sunshine Circuit (Sunshine PCB GmbH). During his tenure overseas, he optimized the company's profit model, vigorously promoted technological transformation, established a quality system, and implemented product structure transformation and management reform at Sunshine Germany, significantly reducing costs while introducing Chinese PCB technology, equipment, and management concepts to Germany. This rapidly improved the company's profits and achieved breakthrough progress in its performance. After returning to China, he vigorously promoted the construction of the company's digital production line and led the completion of multiple scientific research projects. Currently, he has been granted two invention patents and four utility model patents in the field of circuit boards.

Founded in 2001, Shenzhen Sunshine Global Circuit Technology Co., Ltd. (hereinafter referred to as "Sunshine Circuit") is one of the earlier companies in the domestic PCB (printed circuit board) industry to layout overseas. In order to be close to customers and achieve localized services, Sunshine Circuit established branches in Germany and the United States early on.

To implement the company's internationalization strategy, in early 2016, Poetry Hu was officially sent to work in Germany, responsible for the operation and management of Sunshine in Germany. How to quickly adapt to the overseas working environment? How to quickly develop overseas markets? How to adapt to overseas corporate culture and implement cross-cultural management? These are all challenges facing Poetry Hu. Poetry Hu, who had never worked in Germany before, not only turned around the poor operating conditions of the German branch but also gradually overcame the difficulties and challenges encountered in cross-cultural communication and management. After returning to China, Poetry Hu continues to empower the industry. As this article approaches Poetry Hu, listen to the story of our country's technical talents on the journey to the sea.

Sunshine Circuit is anchored in the international strategic direction, taking the lead in the domestic PCB (printed circuit board) industry to layout overseas markets, and is also eager for technical and management talents with foreign enterprise backgrounds. Poetry Hu, who once worked for American and Hong Kong enterprises, has received systematic training from foreign-funded enterprises. When talking about his decision to join Sunshine Circuit in 2006, he used the words "a perfect match."

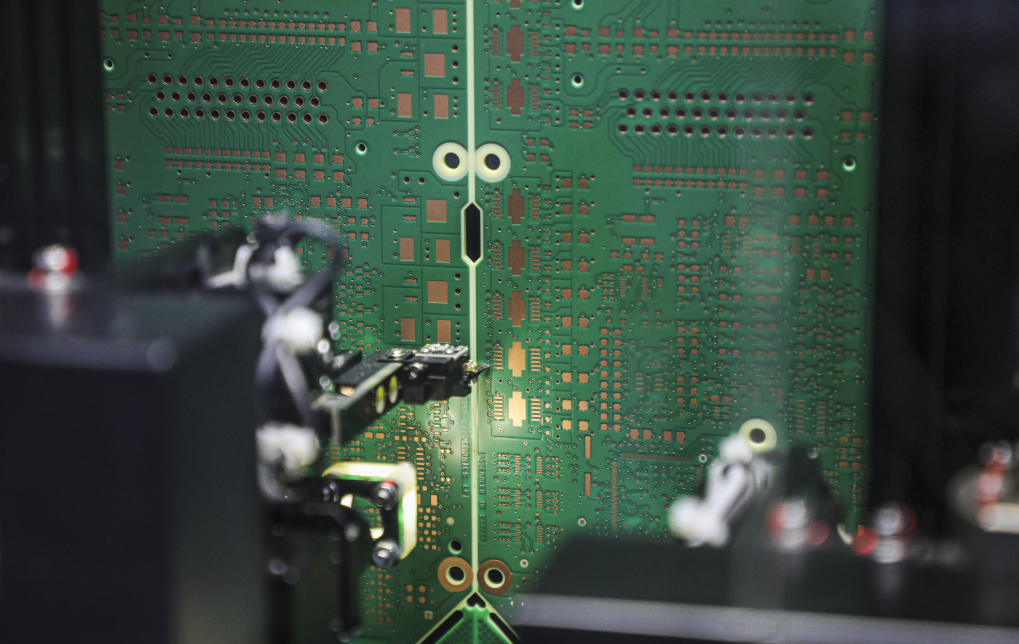

However, the first Spring Festival spent at Sunshine Circuit was the most extraordinary Spring Festival for Poetry Hu. In 2006, Sunshine Circuit transformed to high-end, starting to develop HDI (High Density Interconnect) products. Compared to traditional PCB products, HDI products have higher density of circuit distribution and use a large number of micro-blind buried holes in the design, which requires higher technical requirements and control of the processing process. At that time, Sunshine Circuit had never produced HDI products, and the process flow, processing parameters, and control methods were all blank. Considering the approaching Spring Festival and the tight schedule, facing the high-end stacked-hole HDI product orders received by the company, should they be accepted now or after sampling and groping for experience? The company's management team discussed.

Faced with a rare opportunity, we must seize the momentum. After understanding the specific information of the order, Poetry Hu took the initiative to take on the project. In the absence of most employees' understanding of HDI, Poetry Hu took charge, personally participating in and reviewing every detail from pre-engineering design, process flow setup, processing parameters, and control methods.

The closer to the road to success, the more it is full of risks and challenges. How to design engineering information? How to set processing parameters? How to produce laser drilling? How to control the registration between layers and layers? How to fill the blind holes... In the face of the difficulties that followed one after another in the tight schedule, Poetry Hu led engineers to break through the difficulties one by one, and finally achieved the successful landing of the product.

As the delivery time approached, it was the time when the Spring Festival was approaching and the factory was about to stop work. To ensure the order was completed on time, Poetry Hu stayed in the factory and joined the production line with the front-line employees, delivering the order at the fastest speed in high efficiency cooperation.

Although the road is long, it will reach the end; although the task is difficult, it will be accomplished. Including the time when the factory stopped production during the Spring Festival, in less than a month, Poetry Hu led the employees to achieve the process development and production of these high-end stacked-hole HDI products, and delivered them on time with high yield. As Poetry Hu said, "To tackle technical challenges requires a certain resilience and perseverance, often just a little more persistence will see the dawn and hope."

Sunshine Circuit has been committed to the development of internationalization, with more than 90% of its business coming from overseas, covering Europe, America, and Southeast Asia, and many countries and regions.

In 2013, Sunshine Circuit acquired German RINDE PCB, establishing a production base in Germany. To implement the company's internationalization path and cultivate international management talents, in early 2016, Poetry Hu was sent to Germany to be responsible for the operation and management of Sunshine in Germany.

After taking over the German company, Poetry Hu conducted a systematic analysis of the company's current operating status, optimized the profit model, and redefined the product positioning in conjunction with local conditions, focusing on high-added-value fast board products, providing localized services to local customers and maximizing the value of limited production capacity.

To this end, Poetry Hu eliminated the outdated equipment of the German factory and introduced advanced equipment from China, achieving a "butterfly transformation" in the technical capabilities of the German company to meet the needs of local customers. A series of transformation work on the production line also helped the German company establish a stable quality system, and the product yield was greatly improved.

With many years of experience in the domestic PCB industry, Poetry Hu is very familiar with the domestic PCB industry. He used the synergy between domestic and foreign to purchase raw materials from China, as well as auxiliary materials, drill bits, copper anodes, etc., required for processing, significantly reducing production costs.

However, the implementation of a series of reform measures was not smooth sailing. To go deeper and further on the path of internationalization, whether to answer the question of cultural differences well is also an important step affecting success or failure. Poetry Hu confessed: "A Chinese person parachuting in to manage the entire factory's German colleagues, I did face a very big challenge at the time."

When he first arrived at the German company, although he had good English listening, speaking, reading, and writing skills, Poetry Hu still could not communicate effectively with factory employees. The employees in the German factory were basically local employees, and a considerable part of the employees could not communicate in English. In order to close the distance with employees, Poetry Hu started learning German related to the PCB industry, squeezing out various spare time to understand the local system, laws and regulations, work methods, etc., to integrate into the German team.

Poetry Hu's proactive integration brought him closer and closer to the employees. The team's cohesion and combat effectiveness became stronger and stronger, and the employees were willing to fight with Poetry Hu to promote the company's development. By the end of 2017, the German company's profitability had improved significantly.

the friendship slowly established with the employees, should he return to China or continue to stay here? Poetry Hu once hesitated.

Talking about the original intention of going to Germany, Poetry Hu said, "The assignment to Germany is a very challenging job and a good opportunity to exercise myself. At the same time, as an old employee of the company, I also have a duty to contribute my modest strength to the development of Sunshine in Germany." After 5 years of improvement, the German company has been on the right track. Considering the needs of the domestic company, Poetry Hu chose to return to China at the end of 2020.

After returning to China, Poetry Hu took over the group's product research and development and the operation management of various factories, and coordinated the construction of Sunshine Circuit's digital production line.

After taking over the Sunshine Circuit digital factory project, Poetry Hu made customized modifications to the factory equipment, and at the same time, starting from the process requirements of core products, established a specialized intelligent production line that matches them. After production, Poetry Hu focused on building a high-quality quality system and improving production line yield. A series of ultra-high-layer products of the company, when other factories in the group produced them, the scrap rate once reached as high as 30%, while the digital specialized production line had a scrap rate of only about 2%. The reduction of scrap rate and the improvement of per capita output value allowed the digital production line to achieve profitability in less than half a year after production.

In 2022, Poetry Hu led the overall planning and promotion of Sunshine Circuit's "Cost Reduction Must-Win Battle" project, achieving significant cost savings through continuous process improvement, reducing scrap, and optimizing procurement strategies. Among them, just the increase in board utilization rate alone achieved a cost reduction benefit of nearly 35 million yuan for the whole year.

Nowadays, the fields of artificial intelligence and others are booming in China, driving the continuous progress of PCB towards high speed and high frequency, and the ups and downs of the semiconductor industry are also gradually increasing the requirements for advanced technology for high-end PCB products.

In 2023, Poetry Hu, who has been with Sunshine Circuit for 17 years, has been granted multiple patents in the field of authorized circuit boards, focusing on semiconductor product processing technology, domestic material substitution, automation auxiliary equipment, and special PCB manufacturing techniques. Among them, the results of the Shenzhen Science and Technology Innovation Committee's technical research project "Development of PCB Conductive Filling Material and Application Technology" led by Poetry Hu are expected to achieve domestic substitution.

Currently, affected by the global political and economic situation, the PCB industry is also facing unprecedented challenges. Talking about the development of the PCB industry in Ba'an, Poetry Hu said that as a major manufacturing area of Shenzhen, Ba'an District has a mature and complete industrial chain system and a standardized ecosystem. He believes that the PCB industry can still achieve high-quality development here.