In the electronics industry the moisture-sensitivity level, i.e. Moisture Sensitivity Level (MSL), is a key index used to evaluate the ability of non-hermetic surface-mount devices to resist moisture penetration.

But when facing PCB manufacturers one often cannot get a clear answer—exactly which MSL does a PCB belong to?

This article discusses, from the angles of historical development and industry standards, how the MSL of a PCB should be correctly defined.

According to IPC-T-50N “Terms and Definitions for Interconnecting and Packaging Electronic Circuits”, the moisture-sensitivity level is defined as follows:

An alphanumeric rating indicating a plastic electronic device’s susceptibility to damage due to absorbed moisture when subjected to reflow soldering.

Note that the wording in this definition is “plastic-encapsulated electronic devices”. Why does the definition of MSL involve plastic packages? To answer this we need to trace the history of MSL.

History of MSL

In the late 1980s surface-mount technology (SMT) rose and lead-free soldering was promoted; reflow temperatures soared to 220–260 °C. Plastic-encapsulated ICs frequently cracked during reflow, with internal delamination resembling popcorn popping—called the “Popcorn Effect”.

Plastic encapsulants (epoxy moulding compounds) are hygroscopic; during high-temperature reflow the internal moisture instantly vaporises, and when the steam pressure exceeds the strength of the package material delamination or cracking occurs.

The Joint Electron Device Engineering Council (JEDEC) issued the first moisture-sensitivity test draft in 1993, defining four levels, Level 1–4.

In 1999 J-STD-033 was released: Handling, Packing, Shipping and Use of Moisture/Reflow Sensitive Surface-Mount Devices.

In 2000 the first J-STD-020 was released: Moisture/Reflow Sensitivity Classification for Nonhermetic Surface-Mount Devices, expanding MSL to six levels, Level 1–6.

From the above history we know that the origin of MSL is mainly related to the “Popcorn Effect” of plastic-encapsulated devices, so the definition of MSL carries the wording “plastic-encapsulated electronic devices”. From the historical view MSL never involved printed boards.

Industry-standard definitions of MSL

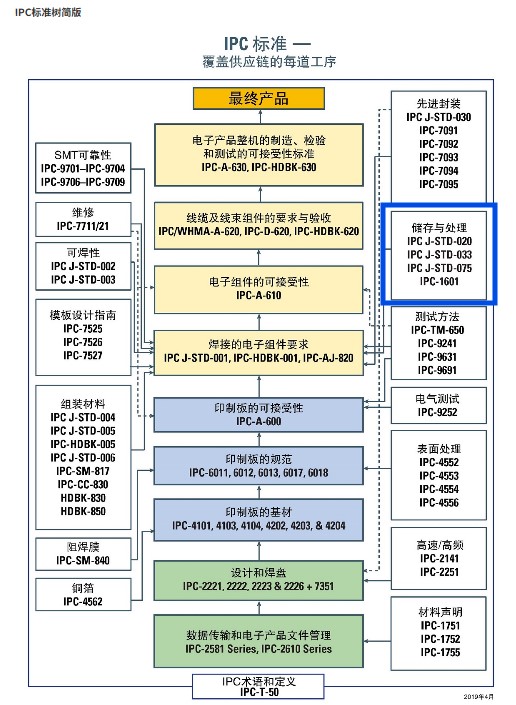

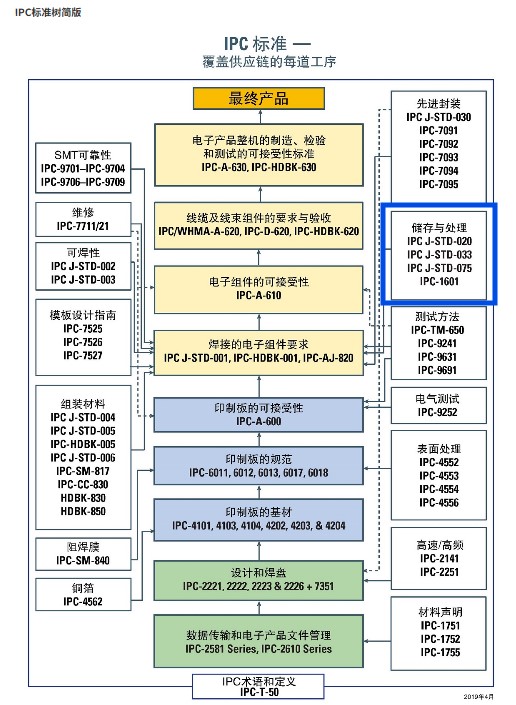

Referring to the IPC standard tree, there are mainly four standards related to storage:

J-STD-020F: Moisture/Reflow Sensitivity Classification for Nonhermetic Surface-Mount Devices

J-STD-033D: Standard for Handling, Packing, Shipping and Use of Moisture/Reflow Sensitive Surface-Mount Devices

J-STD-075A: Classification of Non-IC Electronic Components for Assembly Processes

IPC-1601A: Printed Board Handling and Storage Guidelines (Note: this standard has been superseded by IPC-1602A “Standard for Handling and Storage of Printed Boards”)

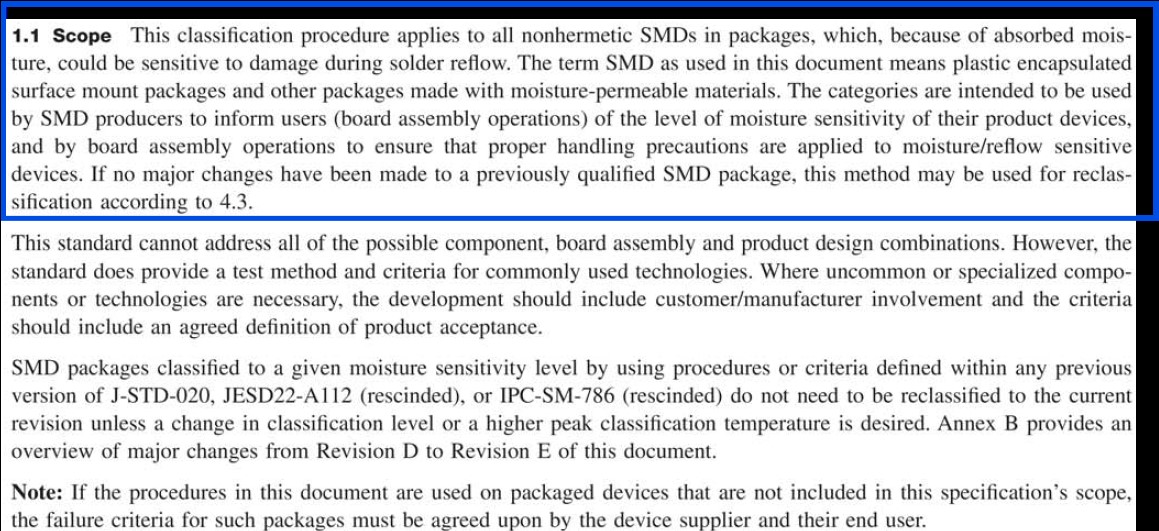

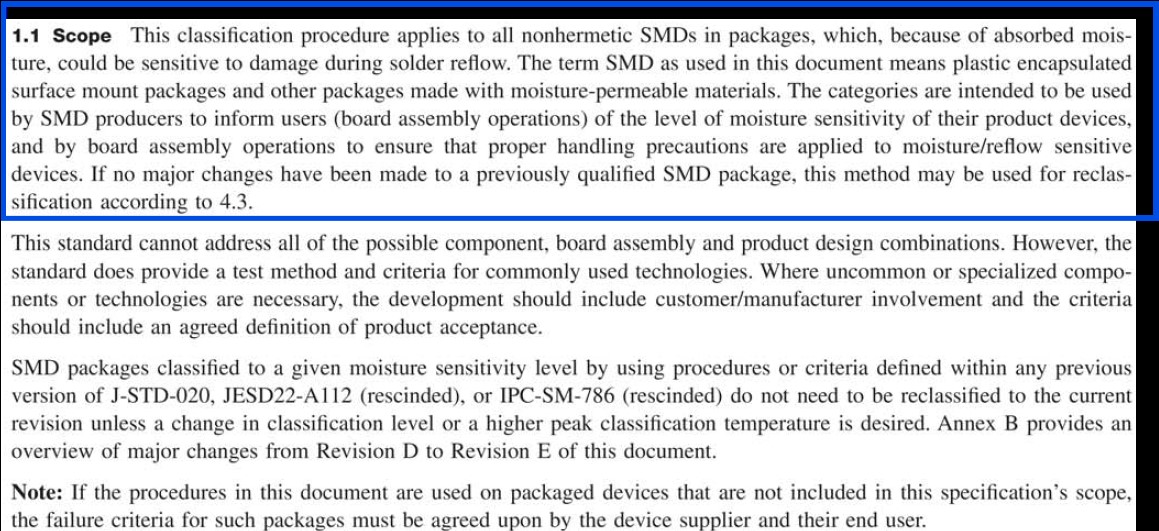

The first, second and third standards do not apply to printed boards. For example, J-STD-020F defines how to classify moisture-sensitive components with MSL levels, and its scope states that it applies to non-hermetic surface-mount devices.

But a PCB does not fall into this category, so the standard is not applicable to PCB MSL classification.

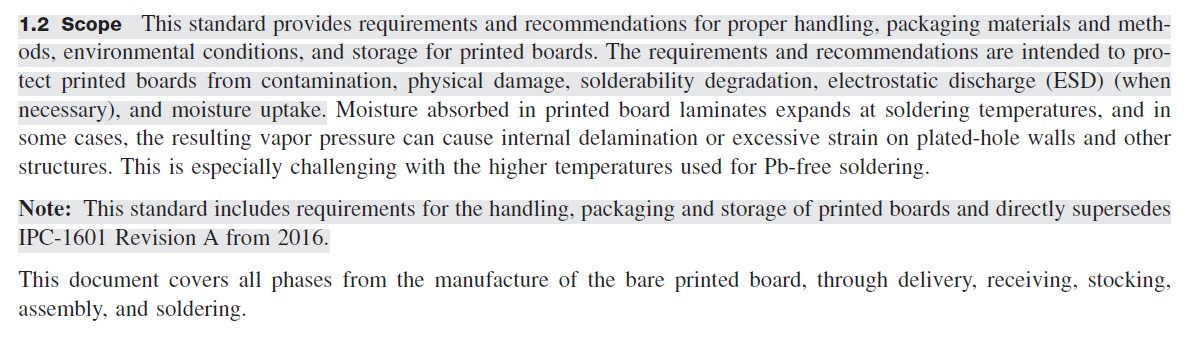

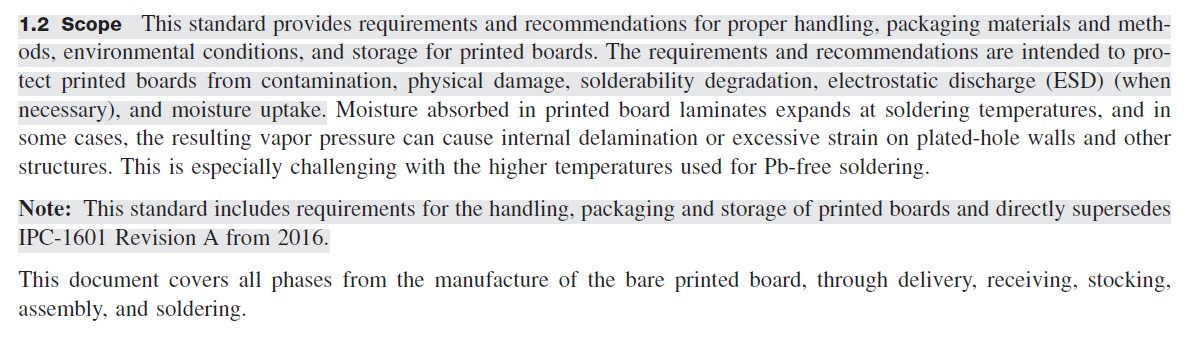

The fourth standard, IPC-1602A, is the one specially aimed at printed boards. It covers the whole process management of bare boards from production, transport, receiving, storage, assembly and soldering.

Below is the scope of IPC-1602A:

IPC-1602A does not give an MSL classification for printed boards. However, the standard gives some recommendations for handling and storage during PCB fabrication.

These are summarised below; please refer to the original standard for details.

Process/Material: bonding material (prepreg and resin-coated foils)

IPC-1602 clause: 3.1.1

IPC-1602 recommended storage: store at < 23 °C [73 °F], < 50 % RH (for some prepregs suppliers may recommend freezer storage)

Process/Material: copper-clad laminates

IPC-1602 clauses: 3.1.2 & 3.2.3

IPC-1602 recommended storage: moisture absorption before etching is small and almost negligible. For etched core boards the standard does not define temperature/humidity requirements, but moisture-uptake risk after etching is large, so appropriate process control or additional baking is needed. Actual board shops also add pre-lamination bake after browning according to material characteristics and risk.

Process/Material: laminated printed boards

IPC-1602 clause: 3.3.3

IPC-1602 recommended storage: after drilling, etching and plating the moisture-uptake risk increases; the standard recommends controls such as dwell-time reduction, but gives no explicit temperature/humidity requirements.

Process/Material: before packing

IPC-1602 clause: 3.3.6

IPC-1602 recommended storage: maximum acceptable moisture content 0.1 %–0.5 %

Process/Material: packing and storage

IPC-1602 clause: 4.1.4

IPC-1602 recommended storage: the standard does not define an explicit temperature/humidity range after packing, but requires the user to perform an assessment to control risk.

From the above IPC-1602A requirements we see that, although there is no explicit MSL level for printed boards (some assembly houses still control PCBs by referring to MSL 3), moisture-uptake risk must be managed during fabrication, and even a baking step may be added.

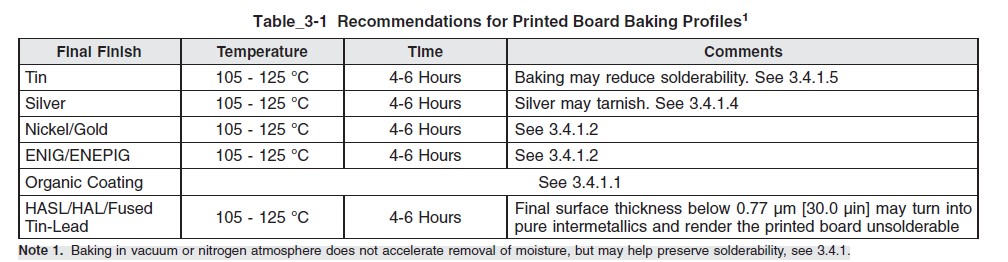

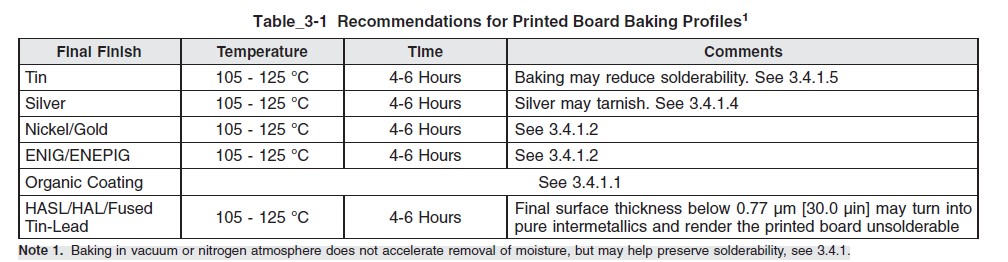

IPC-1602A recommendations for baking are given below, mainly differentiated by surface finish, and emphasise that the solderability risk of surface-finish ageing due to baking must be considered, especially for OSP and immersion silver.

In addition, the resin system of the material is the main factor affecting PCB moisture absorption; rigid-flex boards using polyimide (PI) absorb more moisture than ordinary FR-4 rigid boards and need stricter storage controls. It is generally recommended to bake before assembly (taking into account the effect of baking on the surface finish).

In summary, printed boards (PCBs) themselves are not assigned a moisture-sensitivity level (MSL) under J-STD-020F, because that standard system originated from and targets plastic-encapsulated devices.

However, this by no means implies that PCBs can ignore moisture effects. On the contrary, industry standard IPC-1602A provides whole-process control guidelines for PCBs—from materials, processes, storage to packaging—against moisture-uptake risk.

Therefore, moisture management for PCBs should start with compliance with board-level standards such as IPC-1602A, rather than by applying component MSL levels.