FPC is a printed circuit board made of flexible insulating substrate, which has many advantages compared to ragid PCB. For example, it has high wiring density, light weight, free bending, three-dimensional assembly, and low cost. It has obvious advantages in product styling and reliability design.

The main application areas of automotive FPC include automotive display clusters and automotive electronic devices, engine systems, electric control automatic systems such as seats, doors, and vehicle controls, automotive imaging systems, and automatic safety systems such as sensors. Each vehicle requires approximately 100 or more FPC.

With the rapid increase of new energy vehicles, power battery manufacturers need to improve battery energy density and safety, as well as production efficiency, in order to reduce product costs and enhance overall competitiveness. In terms of wiring harnesses, replacing traditional wiring harnesses with FPC has become a feasible option for power battery companies to introduce new materials into battery PACKs.

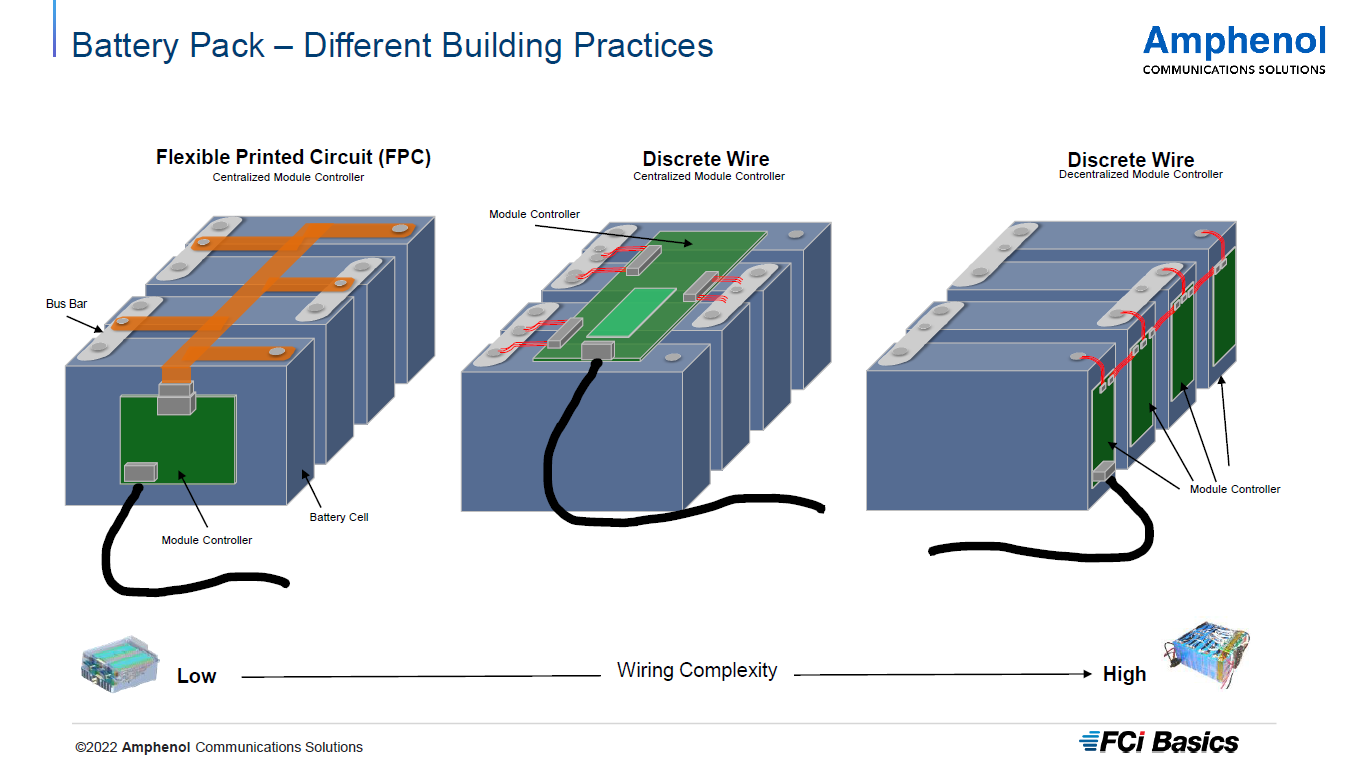

Traditional wire harnesses mainly consist of copper wires and surrounding plastic, with several strands of wire wrapped into an insulator to form a single wire harness. When connecting to the battery, each wire harness must be connected to an electrode. However, when there are many current signals, multiple wire harnesses are required, which inevitably occupies space in the battery pack. In addition, during the PACK assembly process, it relies heavily on workers to manually secure the ports to the battery pack, resulting in instability in both work efficiency and yield.

Compared with traditional wire harnesses, FPC has significant advantages in terms of safety, process flexibility, and automated production. In addition, it has many advantages such as high integration, automated assembly, assembly accuracy, ultra-thin thickness, ultra-softness, and lightweight. The modular and automated production characteristics of FPC can reduce production costs through large-scale production, and at the same time reduce costs by dozens of times in terms of temperature sensing of key components. It can further improve the assembly efficiency of the power battery system. Not only that, the power battery FPC can integrate NTC and fuse on the acquisition board, thus realizing real-time monitoring of temperature and voltage of the power battery, and feedback the acquired data to the BMS. When the safety range is exceeded, the acquisition board fuse will be blown in time to ensure the safe and reliable operation of the power battery.

As an automotive component, the power battery places very strict requirements on the safety, stability, reliability, and durability of FPC. On the one hand, the power battery has temperature and pressure resistance requirements for the FPC, so the materials used in the FPC product must be high-quality and durable. On the other hand, the FPC used for power batteries needs to have functions such as monitoring battery voltage, current, and temperature, and it also needs to be customized according to the shape for production, which determines that mass production requires complex process adjustment and rigorous process testing in advance.

In recent years, with the joint promotion of power battery and FPC manufacturers, through continuous improvement of the process, the introduction environment of FPC in the field of power batteries has been greatly improved, and it is expected that FPC will be introduced into the industry in large quantities.

Article reference source:PCB 行业深度:通讯/消费电子/汽车齐 发力,FPC 替代传统线束前景可期-五矿证券[王少南]

Note: The above content is collated from the Internet, and the copyright belongs to the original author. If there is any infringement, please contact us for deletion.