Product design challenges brought by portability

Unlike fixed-installed equipment, portable electronic devices require more ergonomic design in product design, and the appearance and structural design drive the continuous improvement of assembly complexity.

Portable electronic devices are subject to a variety of physical environmental changes, such as significant physical shock, temperature fluctuations, humidity changes, and solar radiation. This places higher demands on the fastening of circuit connections, the reliability of components and the sealing and durability of external structural components. Unlike fixed installation equipment, which is generally in a controllable electromagnetic environment, portable electronic devices may be carried into various complex electromagnetic environments. Therefore, products must meet high electromagnetic compatibility standards and have strong resistance to electromagnetic interference.

Electronic devices using rigid-flex PCB

The rigid flex PCB makes VR/AR devices lighter and more reliable in assembly

By using rigid-flex PCB for integrated design, the amount of assembly work can be significantly reduced, completely eliminating the problem of equipment errors when using connectors. At the same time, for consumers, the product will become lighter and will not experience device failure caused by loose connectors after prolonged use.

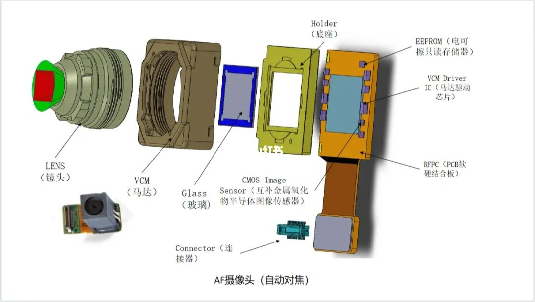

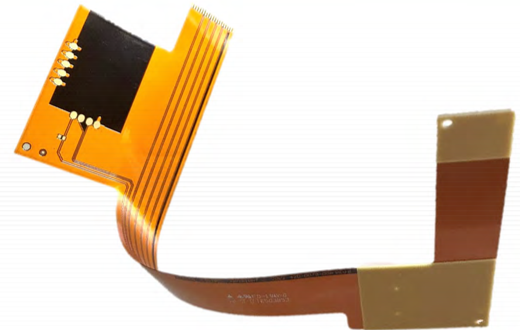

The rigid-flex PCB enables faster and more stable signal transmission for industrial cameras

A large amount of data needs to be transmitted between the image sensor and the ISP (image signal processor) in a short period of time, so the signal transmission rate between the two is very high. By using rigid-flex board design, the signal transmission does not need to go through connectors, and the problem of impedance discontinuity becomes more controllable, thus meeting the requirements of signal integrity.

The rigid-flex board enables the on-board laser radar to overcome various physical challenges

As we all know, the electronic components used in automobiles are all of automotive grade. The car will travel in the hot summer of Turpan and the cold winter of Heihe. The impact of temperature changes will cause thermal expansion and contraction of materials, and after multiple thermal shocks, the connector may loosen. At the same time, during the driving process, various frequencies of vibration will be transmitted to various parts, and the on-board electronic equipment must also meet the requirements of shock vibration.

As a safety component for automobiles, laser radars have higher requirements for reliability and durability. Taking Valeo's third-generation Scala laser radar as an example, rigid-flex PCB are used in the design of the motherboard and laser generator.

Advantages of rigid-flex PCB

No need for connectors, product design can be more compact and lighter

When using rigid-flex PCB for product design, the need for connectors can be reduced, and in some cases, connectors can even be eliminated. The weight of flexible area materials is only about 10% of that of hard board materials of the same size, which can significantly reduce the weight of the product. At the same time, rigid-flex PCB can bend and fold, which gives them an advantage over other types of PCBs when installed in limited space.

Higher reliability

In electronic devices, a large proportion of failures are caused by problems in the interconnection between circuits. In industries such as medical, automotive, and military, products often undergo vibration or drop tests. Flex-rigid PCB provide higher shock resistance and vibration reliability. At the same time, due to the significant reduction in product failure rates caused by the reduction in product interconnection points, product quality is improved while also reducing pressure on product after-sales.

Higher environmental resistance

The rigid-flex PCB has good corrosion resistance, chemical resistance, and UV resistance. In terms of heat dissipation, compared to using a connector design, the rigid-flex PCB can directly extend the copper area of the PCB, expanding the heat dissipation area of the PCB, reducing thermal resistance, and allowing the heat generated during product operation to spread out faster.

Signal Integrity and EMC

The signal transmission of the rigid-flex PCB does not require connectors and cables, which ensures the integrity of the signal during high-speed signal transmission with impedance requirements. At the same time, good shielding design can be implemented in the flexible area to avoid poor shielding contact that often occurs when using cables, which can minimize the EMI radiation of the product itself and external RF interference.

Comprehensive cost advantage

The rigid-flex PCB can directly save the cost of connectors and cables. During the production process, the use of rigid-flex board reduces the number of cable insertion processes, reduces the probability of installation errors, and greatly improves production efficiency.