What is Prepreg?

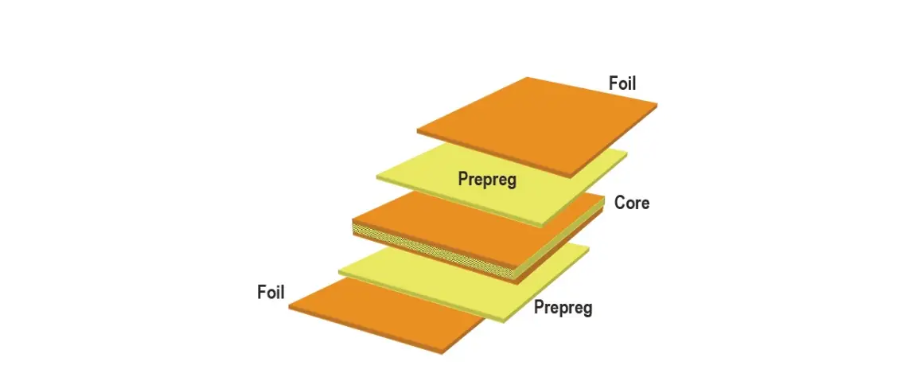

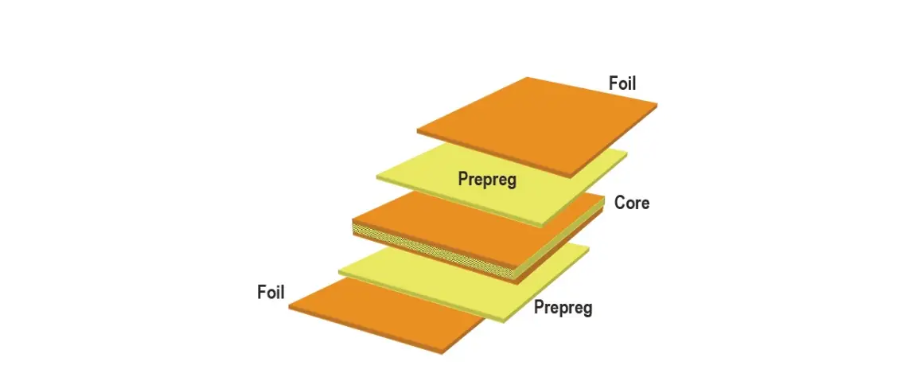

Prepreg, abbreviated as PP, is also called prepreg sheet. In PCB, PP serves as a dielectric layer that provides insulation, positioned between core boards and copper foil or between two core boards.

PP sandwiched between core board and copper foil

Source: MOKO

The resin impregnated on the prepreg is in solid state but not fully cured. During the lamination process, core boards, PP, and copper foil are stacked according to the designed stack-up. Under heat and pressure, the impregnated resin on PP begins to bond adjacent layers. After cross-linking and slow curing, the PCB material properties after lamination start to approach those of the core board.

Prepreg PP is a polymer material composed of glass fabric, resin, curing agent, accelerator, solvent, and additives.

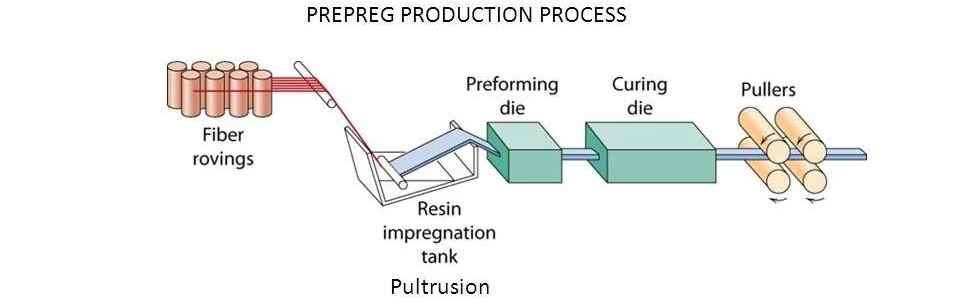

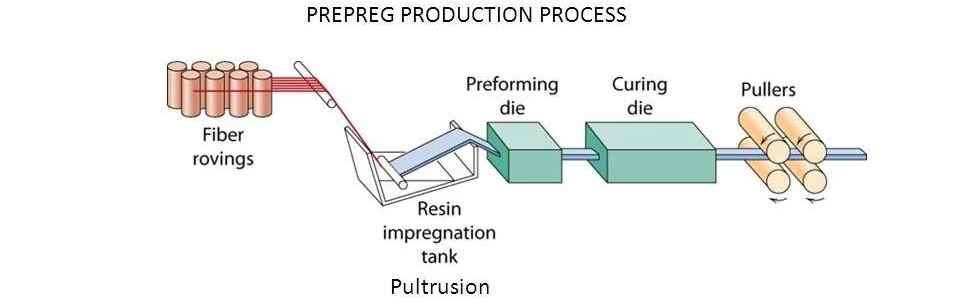

PP production process

Source: partconsulting

Simply put, PP is mainly formed by glass fiber cloth being impregnated with resin and undergoing a series of reaction processes.

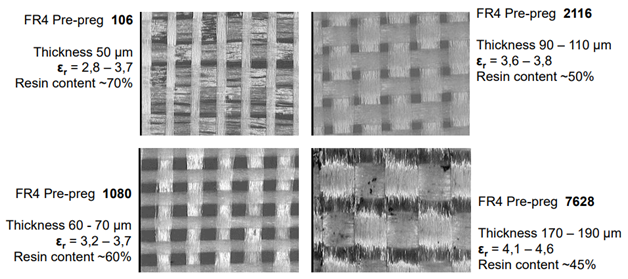

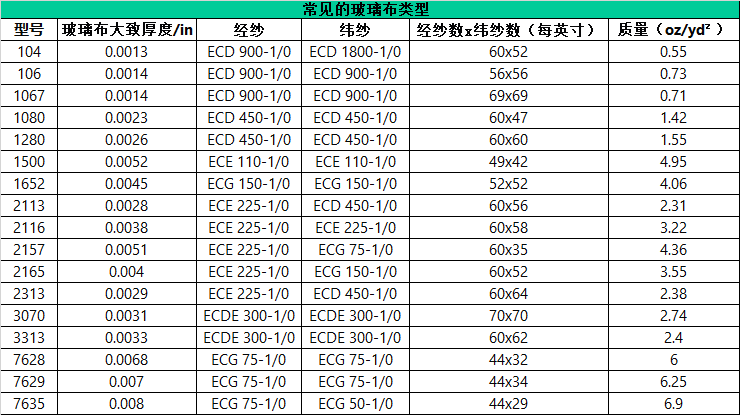

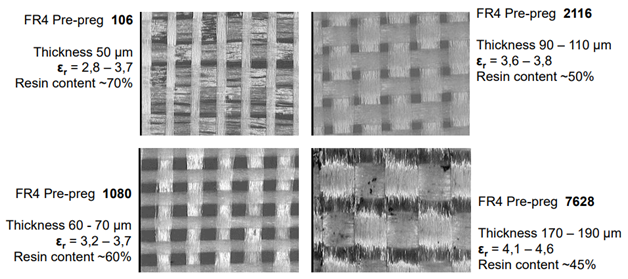

Glass Fiber Cloth: Abbreviated as glass cloth, it is woven from glass fibers. Glass fiber cloth has two weaving directions: the transverse direction is generally called "weft yarn," and the longitudinal direction is generally called "warp yarn." Depending on the prepreg model, glass fiber cloth types and tightness vary. For example, 7628 model PP has much tighter weaving than 1080 model PP.

The gaps and uniformity of glass fiber cloth inside PCB affect signal transmission, commonly mentioned as the glass weave effect.

Performance differences of glass cloth with different weaving densities

Source: Isola

Resin: Epoxy resin is widely used. Other resins include bismaleimide triazine resin (BT), thermosetting cyanate ester resin (CE), thermosetting polyphenylene ether resin (PPE), and polyimide resin (PI).

Parameter Selection for PP Prepreg?

Based on different glass fiber cloth models and resin content, PP comes in various models. When designing PCB stack-up, appropriate PP needs to be selected based on total thickness requirements, resin content requirements, and glass fiber cloth requirements.

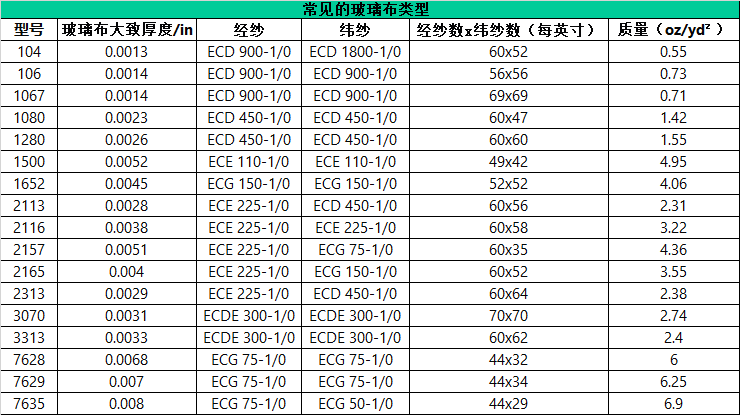

Common glass fiber cloth types are as follows:

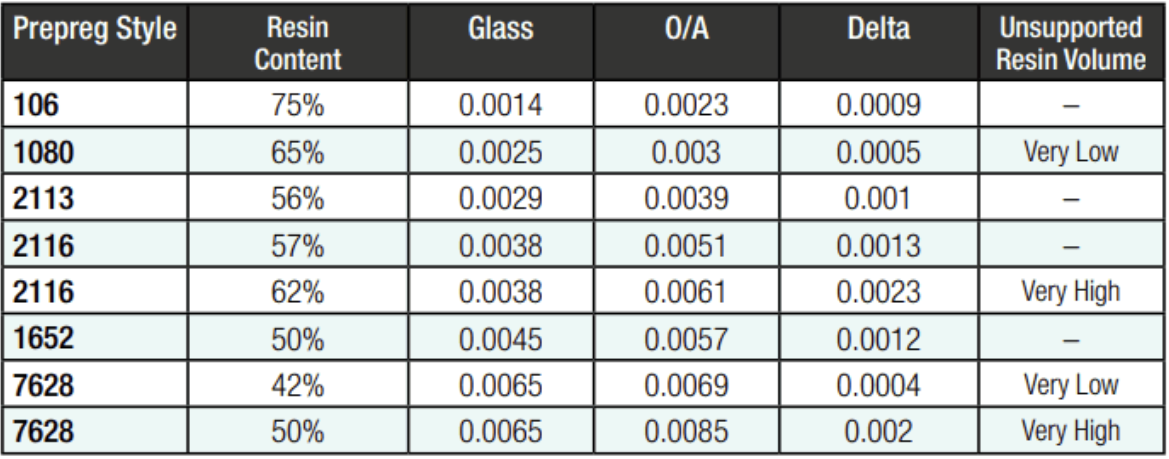

Glass cloth model parameters

PP models are numbered according to glass fiber diameter thickness. Common PP models include 7628/7629, 1506/1501, 2116, 2113, 1080, 1067, 106, etc.

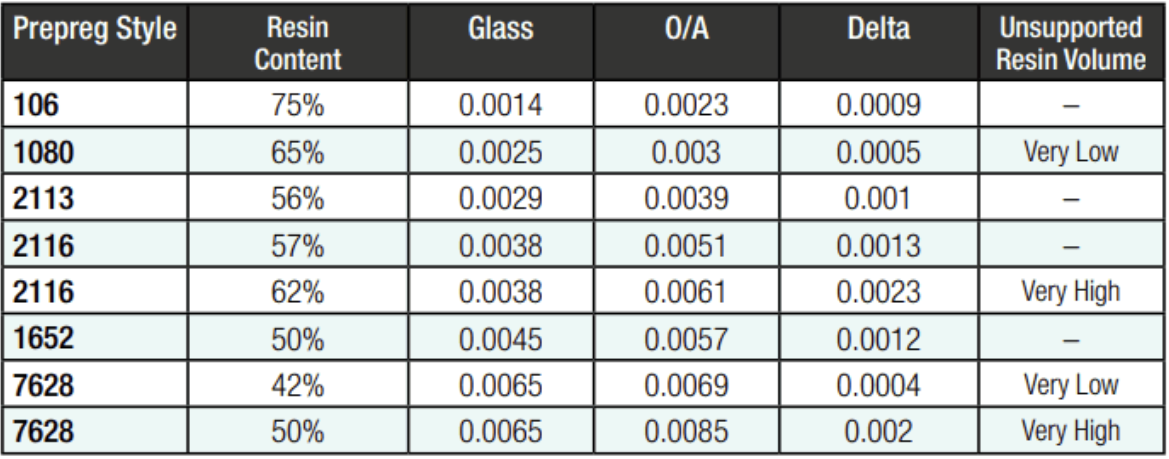

PP model parameters

Different PP suppliers may have different naming conventions for PP models. Generally, larger PP model numbers indicate thicker thickness, while smaller numbers indicate finer glass fiber cloth. PP can be divided into low resin content L, medium resin content M, and high resin content H based on different resin content (RC), such as 7628L, 7628M, 7628H.

Resin Content (RC): Represents the weight percentage of resin in PP. For the same PP model, higher RC values result in thicker PP thickness and higher price.

Resin Flow: Represents the percentage of flowable portion in the resin relative to total resin amount. In PCB lamination process, excessive resin flow can easily cause resin shortage. Insufficient resin flow makes it difficult to fill pattern gaps, creating bubbles and voids.

Gel Time: Represents the total time resin remains in liquid flow state under heating conditions. Longer gelation time allows resin sufficient time to wet patterns and effectively fill patterns, beneficial for PCB lamination process parameter control. If gelation time is too short, air trapped inside the board cannot be removed before PP is completely cured, forming bubbles and other anomalies.

Volatile Content: Refers to the weight percentage of volatile components lost after PP drying relative to original weight.